Infrastructure

Our Office & Staff

Together We Thrive

At Kalra Papers, our office staff is the heart of our operations. Together, we create a collaborative environment that drives innovation and excellence in everything we do.

We are dedicated to providing top-quality paper products while fostering a culture of teamwork, integrity, and sustainability. Every member of our team plays a vital role in achieving this mission.

Wherehouse

Reliable Inventory Management.

At Kalra Papers, we understand that efficient warehouse management is the backbone of our operations. Our commitment to excellence ensures that we provide top-quality paper products while maintaining streamlined logistics and inventory control.We continuously monitor key performance metrics to enhance our operations, ensuring that we deliver not just products, but also quality and reliability.

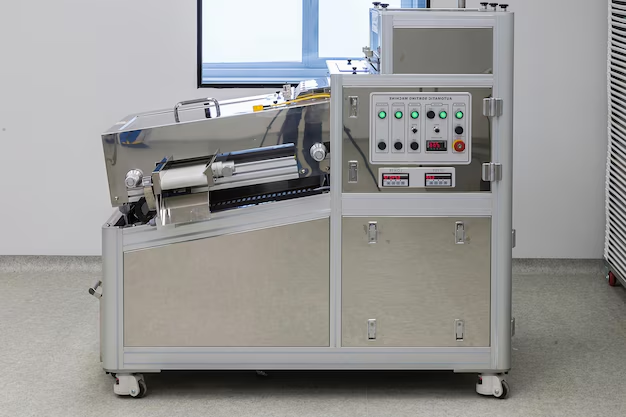

Cutting Machines

Precision Meets Efficiency

At Kalra Papers, Our SM Helix Sheet Cutter Machine with a 1700mm deckle width and a speed of 350 meters per minutes is designed for precision cutting of large sheets in various sizes. This industrial-grade machine features a robust construction that ensures durability and stability during operation. The machine utilizes a helix cutting blade that provides smooth and accurate cuts, reducing material wastage and ensuring high-quality finishes.

Bundling

Bundling with care

To efficiently bundle paper products for storage and transportation, ensuring quality and reducing damage during handling.

1. Clear a designated area for bundling to ensure a smooth workflow.

2. Identify the type and size of paper to be bundled (e.g., sheets, rolls, boards).

3. Sort papers according to customer orders or specifications.

4. Inspect each sheet for defects, ensuring only quality products are bundled.

5. Stack the paper sheets evenly, ensuring they are aligned properly.

6. Maintain a consistent number of sheets per bundle based on order specifications.

7. If bundling multiple sizes or types, ensure each type is stacked separately before bundling.

8. Wrap the straps around the bundle tightly but not excessively to avoid damage.

9. Ensure labels are clear and securely attached.

10. Place completed bundles in designated storage areas for easy access.

Wrapping

Every layer counts

To efficiently and securely wrap bundles of paper products using a wrapping machine, ensuring protection during storage and transportation.

1. Ensure the wrapping machine is clean, properly maintained, and set up in a designated wrapping area.2. Inspect each bundle to ensure it is securely tied or strapped and free of defects.

3. Verify that the bundles conform to order specifications (quantity, type, etc.).

4. Place the bundle on the machine's platform, ensuring it is stable and correctly aligned according to the machine’s guidelines.

5. Set the wrapping machine parameters based on the size of the bundle and the type of wrapping material being used (e.g., film tension, wrapping speed).

6. Organize wrapped bundles according to delivery routes or shipping schedules.

7. Conduct a final check on wrapped bundles to ensure they meet quality standards and specifications.

Dispatch

Fast and efficient

At Kalra Papers, we prioritize efficiency in our dispatch process to ensure we can deliver maximum quantities in a single day. Here’s how we achieve this:

1. Streamlined Order Processing.

2. Dedicated Workforce.

3. Advanced Inventory Management.

4. Optimized Packing Procedures

5. Strategic Logistics.

6. Scheduled Dispatch Slots.

7. Continuous Improvement.

8. Flexible Resource Allocation.